The Helix Pitch is not an exclusive term for helical gears, if it can be mentioned, in a screw, the helix is the thread itself, in the same way, a helical drill bit for metal has two helixes, which are the channels for where the chip comes out and, what this post comes to, is the example that generates the most confusion, the case of the helix and more specifically, the helix pitch in Helical Gears.

To explain it, it is necessary to understand a very simple example, the case of a normal screw.

The screw has several elements that compose it, such as: the head, the body, and the thread.

The thread is the machining of shape, which can have multiple geometries, for example a triangle, a square, a trapezoid, a radius, etc.

Threads is also characterized by having a constant distance for each revolution or turn of the screw.

That is, the pitch of the thread.

This concept, the pitch is the key to understanding what the Helix pitch is.

Suppose that our screw has two starts, this means that there are two helixes, therefore the real pitch of the thread increases.

Understanding by real pitch, the effective machining distance, or the distance between crest and crest of a helix or start.

Continuing with the example, if the screw has three starts, in the same way, the actual pitch of the screw increases, as does the number of screw helices, which are now three.

Helix Pitch: A helical cylindrical gear is a multi-start screw.

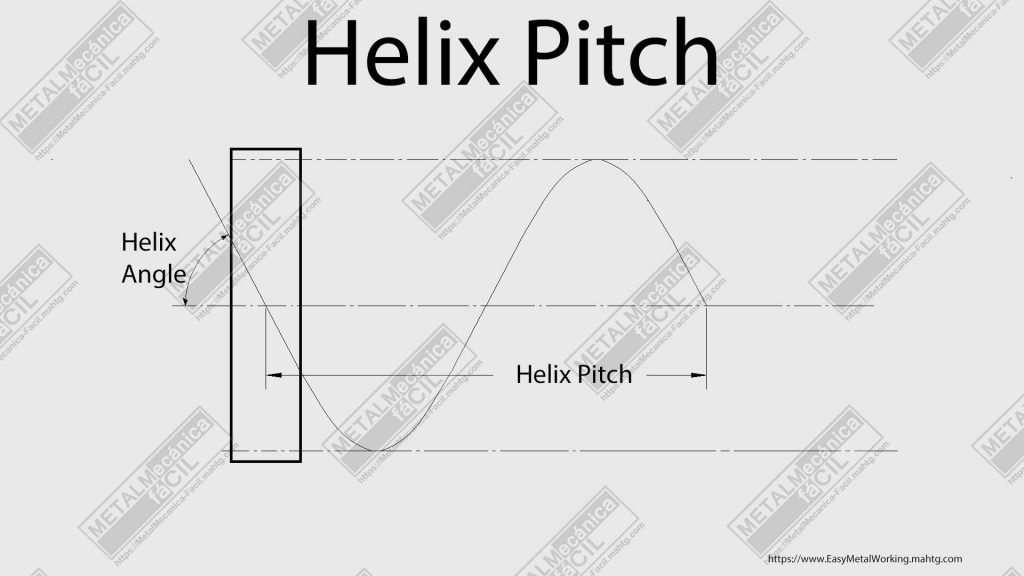

As has just been seen with the case of the multi-start screw, the helical cylindrical gear is a screw with several starts or helixes, therefore, with large real pitches, but with these gears, the real pitch name changes to Helix Pitch, as shown in the following graphic:

The Helix Pitch in a helical is directly proportional to the pitch diameter of the gear, this means that if there is a small pitch diameter, the pitch tends to be small and vice versa.

And the pitch of the helix is inversely proportional to the tangent of the helix angle.

The formula to find the it (Hp) of a metric helical cylindrical gear is as follows:

Hp = (Pd * PI) / tg alpha.

Where:

Hp: is the helix pitch gear.

Pd: is the Pitch diameter of the gear.

PI: is 3.1416.

alpha: is the angle of the helix or gear tooth angle in the pitch diameter.

You are interested in this: How to Copy a Metric Helical Gear

In general, although it is not a rule, the values that the calculation of the helix pitch of a helix yields are large values, which is why a relatively easy way and within reach of a workshop that has a milling machine, a dividing head and a gear train (banjo set), is precisely, execute these tracings by using the universal milling machine.

I hope this information helps you and can be of use to you.

If so, I ask you to please rate me with the highest star score, right here below this article.

Please, subscribe to my YouTube Channel!